ABMS Consultants can conduct a detailed analysis of various parts by using the Finite Element Analysis method to allow for an optimized and refined design. Our qualified Professional Engineers are able to solve complex problems typically found in the industry.

Our finite element analysis (FEA) are varied:

- Static linear and non-linear analysis

- Buckling analysis

- Computational fluid dynamics (CFD)

- Thermal transfer analysis

We also advocate the use of finite element analysis as soon as possible in the design and development process. We also have a lot of technical knowledge and practical experience in numerous domains. All of this is at your disposition.

Realisations :

- Overheating Analysis of a 9 MW Alternator

Analysis of a fluid flow using the finite element analysis method (CFD) and mechanical design of a sheath to solve a problem where the existing alternator of a hydroelectric turbine overheated. Technical challenges were numerous:- Bad design of existing sheath;

- Minimal space for the installation of a new plenum;

- Minimize the new fan noise;

- Airflow optimisation.

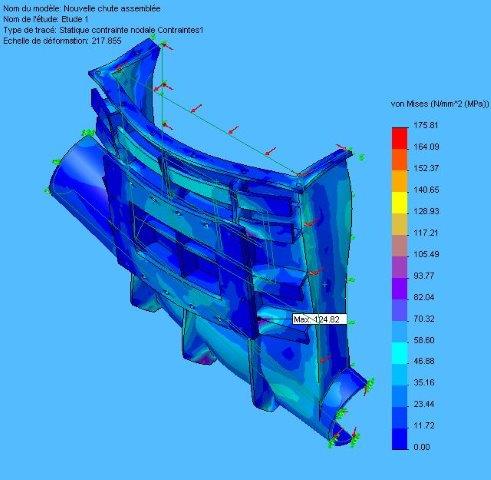

- Screw Conveyor

Modification of an existing discharge chute in order to resist to the required pressure by a new process. Additional stiffener plates were included and optimized in the design, near the manhole.

- Oil Separator

Optimisation of the fluid flow in a water-oil separation system where water speed is critical to the whole system’s efficiency.