ABMS Consultants can design custom safety solutions based on your specific requirements, while also taking into account the reality of a construction site. For example, we can design lifelines and lifeline brackets, anchor points, multifunction work platforms, guardrails, and much more. We can also write procedures and implement a temporary solution for your operations.

Work Optimisation :

The ABMS team designs structures and custom equipment for your work at height, for hard to access places and for specific tasks where a controlled environment is required. This allows your facility to be safer, to offer a better ergonomy to your employees and to reduce production downtime. These factors contribute to increase the performance of your workers while protecting them effectively.

- Specific platform design for a specific job

- Nacelle or man baskets

We design platforms, nacelles and other devices tailored to your operational reality and of to your installations. For example, your platform can be adjustable, removable or retractable. It can also incorporate a guardrail or a removable section. In fact, every option is offered to your business to ensure that it can adjust adequately to every step of your work, in order to simplify and optimize it.

Worker Protection :

- Lifeline

- Anchor points

The ABMS team designs lifelines and custom anchor points to fulfill your specific needs. Do you need a lifeline for two or four workers? A non-standard anchor point? ABMS designs exactly what you need to protect your employees.

Safe Lifting and Handling :

Our team has a solid experience in the manufacturing domain, thanks to the design and certification of numerous lifting beams, spreader beams or other specialized tooling. For more information, consult our Lifting and handling devices page.

Procedures :

- Work procedures

- Safe linfting and handling procedures

ABMS can elaborate safe work, lifting and handling procedures tailored to your requirements. This can include simple operations, such as flipping over or transshipping a large part in a confined space or handling parts close to electrical power lines.

In every case, we respect the applicable standards, the CNESST Safety Code for the construction industry, the WSIB rules (Ontario), the WorkSafeBC rules (British-Columbia), OSHA rules and the Canadian safety regulation that applies to your situation.

Realisations :

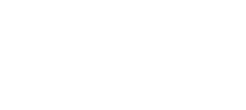

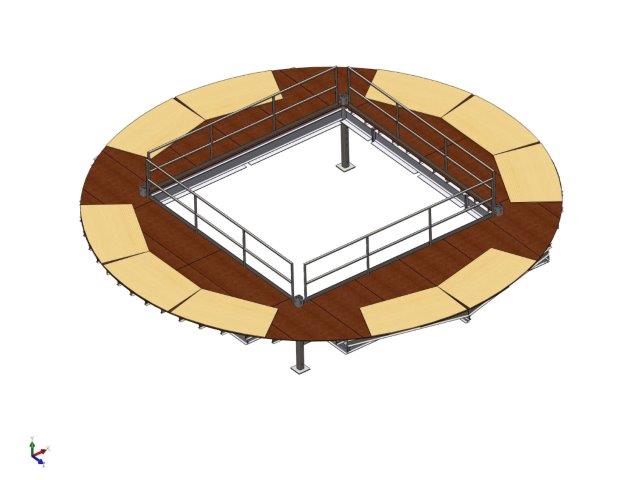

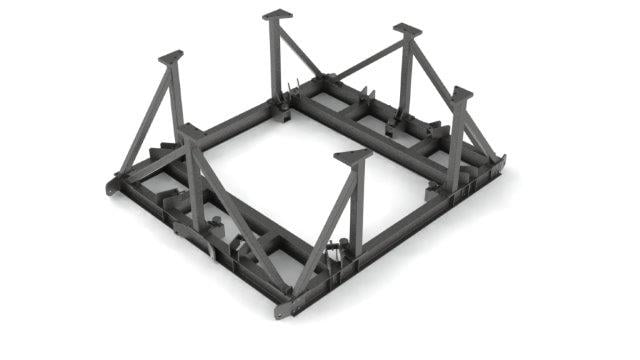

- Stator Assembly Platform

Design and emit technical drawings of a temporary work platform that can support heavy loads. The challenge was to design a self-supported, removable, diameter and height adjustable and easily transportable platform. It also needed to include a removable central section. This platform complies with the Quebec safety code for the construction domain.

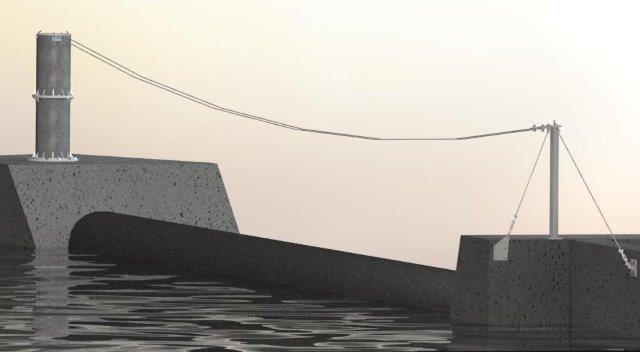

- Custom Lifeline

Working on a hydroelectric dam can be dangerous. Operators must be attached to a harness. When fixed attach points are not acceptable, a custom lifeline can be installed in accordance with the local regulations and CSA standards.

- Support for a shop-assembled distributor and its transportation

Handling hydroelectric equipment can sometimes be tricky because of their large size. The ABMS team designed a support for an extremely costly and heavy part (distributor) for its transportation to the dam. Because of this, our client was able to build the distributor in its shop instead of the traditional method at the hydroelectric dam.

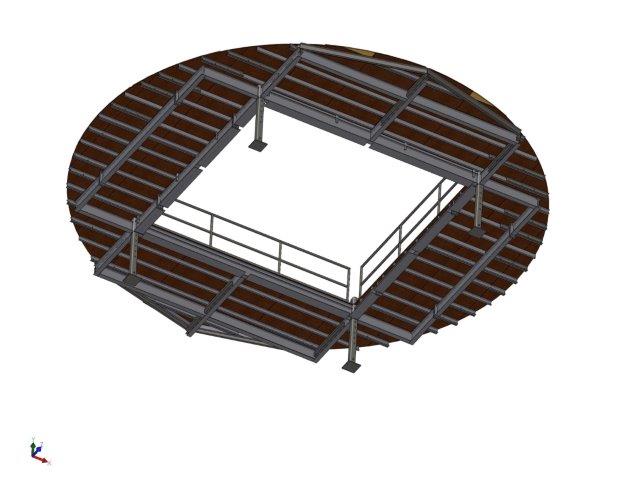

- Roof Platform

Our client needed to replace electrical insulators on the roof of its power plant. The roof structure did not allow the transport of the insulators directly on the roof or the use of a large crane. The ABMS platform was designed to allow our client to move the insulators with a bogey and to use la light crane in order to proceed with the installation of the insulators.