ABMS Consultants can deliver complete, precise and clear hazard and risk analysis for your whole facility or for a single machine. We develop solutions in line with the operational requirements of your machines. With our report in hand, you will be able to elaborate a concrete and efficient plan that targets the prevention of work-related incidents. You will also be able to prioritize the steps that must be undertaken to secure your facility.

Our services :

Because we are very flexible, we offer many services related to machine safety:

- Machine inspection based on our simplified and customized approach;

- Design of protection devices (fix, mobile and motorized guards);

- Certification and validation of safety-related equipment after installation;

- Elaboration of an action plan;

- Validation of the electrical protection system by categories;

- Project management;

- Support during installation;

- Manufacturing and installation;

- Complete turnkey service.

Our role :

Our role is to support you in your process of securing your work environment to make sure it is compliant with the most recent standards and regulation, while sustaining your productivity level.

- Analyze risks;

- Secure the work environment of your employees;

- Make sure that your facility respects applicable laws and regulation;

- Identify and evaluate potential dangers;

- Find possible solutions to secure your machines and equipment;

- Create a list of actions to be undertaken, prioritized by importance.

Realisations :

- Machine Safety, Risk analysis of a carpentry and tinsmith workshop

Inspection, risk analysis, elaboration of a recommendation list and prioritization of 48 machines in a carpentry and tinsmith workshop. ABMS also completed the validation of existing safety measures already installed on various machines. The project included the analysis of numerous standards, atypical and customized machines.

- Worker Safety, Maintenance nacelle for trolley-lift in accordance with CSA B56.1

Analysis and modification of an existing trolley-lift nacelle in order to make sure it complies with the occupational health and safety Regulation (RSST) of the Quebec province and the CSA B56.1 standard. Amongst other things, we have rigidified the structure, added one harness anchor and added an intermediate rail to the existing guardrail.

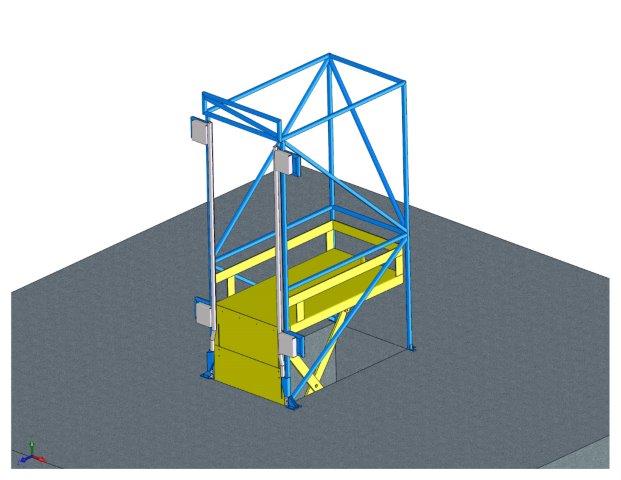

- Machine Safety, Custom lift table for atypical use

Following a dramatic work incident, we have been commissioned to design a custom lift table that permits safe work by employees while maintaining productivity and operational flexibility. The structure around the new lift table eliminates pinch zones. The unique door locking mechanism is danger-free. Sensors were also installed to prevent table movement when in dangerous conditions.

Note : Safety grating not shown to highlights the main components.

Note : Safety grating not shown to highlights the main components.